To deliver the finished goods to a buyer, merchandise needs to procure good quality of carton box according to buyer’s standard. Carton box should be strong enough to protect the finished goods. If carton box quality not good enough to protect the goods, then the goods may damage during transportation and buyer will claim for any damage if occurred. To ensure the carton box quality some buyer asks to do a busting test of carton box. You should put two ply boards on upper side and bottom side of the carton box to ensure product security.

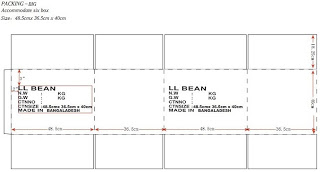

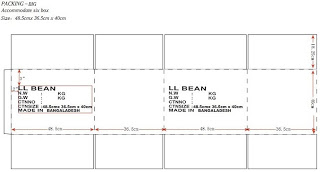

First fix the carton box dimension, quality and then fix MCQ (Master carton quantity of each style i.e. How many pieces would be packed in a carton box) for exportation.

Now, I will show you how to calculate a carton box and ply boards cost according to buyer specification.

Carton box MOQ could be negotiable depends on supplier’s wiliness but I worked those suppliers, they do not maintain any MOQ.

During carton box order, the following issues need to be clear to a supplier to erase hassle.

* Type of raw material and quality

* Sealing mechanism

* Comprehensive strength of carton box

* Size of shipping mark and placement need to be mentioned clearly

* Brand logo/Warning logo or any special info need to be printed.

* Number of colors or color specification etc.

Lead Time:

The normal carton box can be supplied by the supplier within 4-5 days after order placement but if having special design or dimensions, it will increase the lead time up to 08-10 days upon its features. Some industry is the pioneer in transforming the carton industry by converting 7 ply cartons into 3 plies, saving cost, space in addition to contributing to an environment through less pulp consumption.

I am giving another excel format to know the details. Just input the carton box dimension and then fix carton box quality and ask the supplier to provide per SQ F price. Then you can get carton box and ply boards cost by yourself.

Please find a google drive link to download the excel file to figure out carton box costing individually. Please hit the link to download your desired file.

If anyone doesn’t understand the formulas clearly then please ask me for assistance. If anyone failed to get the “excel format” from my link, then please inform me to your required file. I will show my level best effort to provide your desired file as soon as possible through mail.

You may like: SOP of Packing Operator

Leave a Reply

You must be logged in to post a comment.