The importance and necessity of a pattern maker in apparel industry are inexpressible. A pattern maker is capable of converting fashion designers imagination or thought to become visible. A pattern maker is he who makes garment pattern based on Fashion Designers/Design team provided idea/sketch. The sustainable of a design mostly depends on pattern makers expertise, efficiency, and capability. As all we know fabric is the main element of a garment item which contains about 50% (percent) of the total value. So, if 1% fabric cost is possible to save by efficient pattern maker, this will increase average profit margin. So we can easily realize the significance role of a pattern maker in apparel industry to gain profit margin. Thus, owner of garment industry always gives high priority for making an active pattern design team to minimize production cost.

A pattern maker working procedure has mentioned below.

A) Work Sheet Review

1) Have to review all the packages/program completely point by point for clear understanding. For this task, pattern maker should consult with concern merchandiser regularly.

2) Ask merchandiser to provide all necessary information or development manual to review.

3) Have to confirm all the packages are clearly understood. It will be better if receive any reference sample from buyers end to review.

4) Have to know sample development schedule and dispatch time before starting pattern.

5) If you have any confusion or unclear point, should clear it before start pattern making.

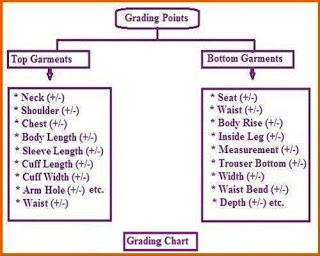

1) Check previous season or buyer mention block to avoid fit problem.

2) Check block measurement and write beside of new style measurement sheet.

3) Should carefully rectify block for a new style.

4) Consider measurement loose for sewing, refer to previous similar style.

5) Consider the design line from mark sample or sketch.

6) If available copy pattern construction from the previous style.

7) Should use mark and pin sample to make new style pattern.

8) Should apply update comments to avoid any missing and mistake.

C) Style Pattern

1) Before creating a new style, pattern maker has to understand all the construction clearly.

2) Have to understand the importance of notches, interior & exterior design details.

3) Have to understand seam allowance requirements based on machine & product construction.

4) Add fabrication as mention BOM with compare sketch details.

5) Proceed to make lining pattern from shell pattern based on style.

6) Check the full style pattern again ones ready, Like Join seam, fabrication, notches,

Internals, seam allowance, and all parts are created.

7) Pattern maker should make some mock up for critical points to fit the sample and consult with seniors if necessary.

8) To make washing style pattern, pattern maker has to consider fabric shrinkage percentage and pay extra care to erase measurement problem.

D) Marker Making

1) Have to make a correct model with all the pattern and correct fabrication.

2) Before start the marker, pattern, and marker man have to check fabrication with fabric type and all pattern pieces are there to avoid any missing and mistake.

3) Marker man should collect all the fabric width information.

E) Sewing Pattern

1) Have to study buyer spec sheet clearly and sketch details attentively and follow all of their sewing pattern guidelines.

2) Have to print out all needed pattern and be ready for sewing.

3) The entire finish pattern should be plot finish pattern, should not with allowance.

4) Seniors should confirm all the important position.

Beside this a pattern maker has to maintain below responsibilities:

As we know if a pattern maker makes a mistake it will bring great loss to concern garments company. So, garments owner should emphasize on pattern section and give them a good working environment with motivation. It’s human nature that whenever they get more, then they will pay more attention to their duties.

1) To be energetic for the development of patterns regularly and no compromise against product quality & measurement.

2) Have to find out quick solution against any problem arisen regarding patterns during bulk production and identify root causes to erase hassles and take prompt corrective actions.

3) To be sincere to fulfill the pattern demand of buyers to improve the product quality.

4) To keep up communication through e-mail or another way with the concern parties.

5) Motivate and give training to subordinates to enrich their skills.

6) Communicate with Merchandiser, CAD, Cutting, Printing, Embroidery, QC and Sewing floor for any functional requirements.

7) Hardly devoted to achieve the company’s goal.

8) Promptly implement the instruction of higher management.

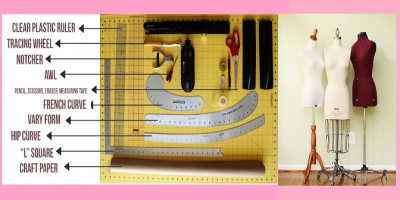

9) Should have sound knowledge regarding the utilization of equipment/machinery in production floor to ensure the product quality during pattern making.

Note: All the pattern maker should follow this entire guideline perfectly without fall to minimize the mistake. We should realize that our whole attempt might become in vain if the pattern maker not maintains the above instructions strictly and not finished his task carefully. It will be better if there a cordial relation between pattern maker and concern merchandiser to expedite above task. You are requested to click my google drive link to get a fantastic guideline regarding pattern making process. Please hit the link to download your desired file.

You may like: Methods of Marker Making

Leave a Reply

You must be logged in to post a comment.