In the contest of manufacturing sector production efficiency is the most burning elements. All efforts might be gone in vain if the output quantities of finished items are not satisfactory what you desire from the production line. Production efficiency is considered as number of finished goods by consuming total manpower and machinery in a particular time.

We can figure out per day production output from a particular line or unit by following formulas.

Production efficiency per day = (Total working hour x Number of machines x Unit produced by operator per hour)

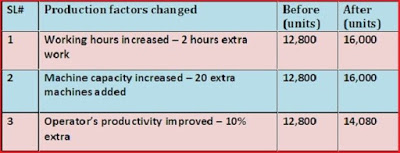

Please find a chart to watch the improvement of productivity after taking the initiative in the production process.

Suppose, if a garment production floor has 80 machines and working time is 8 hours per day. Each operator is capable of producing around 20 pieces polo shirt per hour then end of the day production quantity will be?

Production quantity per day = (80 x 8 x 20) = 12,800 units.

How can we improve productivity?

There is a close relation between above three factors. Let’s find the intimacy of these factors.

1. If the number of total machines is increased to get extra productivity what would be the total outcome? Only boost up of machinery is not a better solution unless we increase operators proportionally. To optimize the output of the new machine need additional skilled workforce. Suppose, if machine quantity increase from 80 to 100 then production units will be 100 x 8 x 20 = 16000 units/day.

2. Productivity can be increased by prolonging the working hour. Suppose, if operators working time increase from 8 to 10 hours then what will be the effect. Productivity must be increased, and factory may desire more units than earlier 80 x 10 x 20 = 16000 units/day.

3. Productivity can be improved by increasing operator’s quantity. But machine and equipment’s need to be increased proportionally according to operators otherwise manpower becomes idle due to lack of equipment’s.

4. Productivity can be improved by some other ways like motivation, training or skill improvement program. It has been observed that around 10% of productivity can be increased by giving higher training and motivation. Suppose, if operators produce 20 pieces per hour before, but after giving training, they will produce 22 pieces. So, factories production unit will be 80 x 8 x 22 = 14080 units/day.

5. Productivity can be improved by implementing modern technology. Some working step can be minimized or removed by setting up computerized advanced equipment instead of human beings. Besides this, some unique working method can be implemented for smooth production process like Lean Sigma, GSD, Work study engineering etc. Then, factory may desire more units than earlier.

You may like: Groundwork for stepping into Bulk Production

Leave a Reply

You must be logged in to post a comment.