The world is changing rapidly. Human fashion trend is also changing more quickly. So dress making industry needs to apply new techniques and equipment to cope up with this advancement simultaneously. Thus, automation in ready-made garment industry is in demand of time to improve product quality, productivity, and expedite production capacity. The primary motto of automation in the apparel industry is to reduce production cost to survive in the competitive market. As all of we know, “more productivity means more profit.” Beside this globalization insists apparel industries to jump up production capacity by reducing production cost.

There are numerous competitors exists in the apparel industry, and they are ready to occupy your market in any case. So you should look forward and take the initiative to install modern technology to stay alive in the versatile fashion world. It is remarkable that only installation of modern technology may not give you a significant benefit. You should emphasize on the training program of your existing workers to get full advantage of modern equipment. That new equipment and techniques will give you a bunch of benefits though it exists some demerits. Let’s discuss some merits and demerits of automation in the apparel industry.

Merits of automation in apparel industry:

1) Shorten your production lead time

2) Increase productivity

3) Minimize workers quantity

4) Increase product quality

5) Increase workers efficiency

6) Enhance organizations goodwill and prominence

7) New equipment and technology can save your floor space

Demerits of automation in apparel industry:

1) Installation of modern equipment and technology require big amount of money

2) To operate new equipment require skilled operators and technicians

3) To enhance present workers efficiency requires training

We can work in the following section to apply automation:

1. Cutting: Cutting section productivity may improve by introducing new equipment and technology. Several types of auto cutting machine like auto fabric spreader, band knife, computerized CAM cutter, Auto arm cutting machine, Die cutting machine, Laser cutting machine may help you to get optimum result.

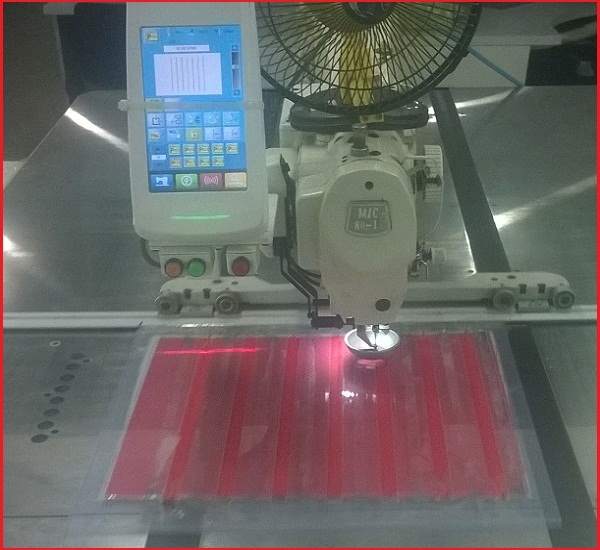

2. Production Floor: It is one of the perfect places in the apparel industry to apply new technology to boost up productivity. New equipment and method can improve product quality as well as efficiency. This new equipment can minimize some process. Suppose automatic mold sewing machine can sew straight quilting line or zigzag stitch, cuff, collar, j-stitch, zipper garage to reduce main stitching line operations. Cycle check machine can sew particular area quickly. Those sewing machines have integrated computerized intelligence system that can perform according to command.

3. Embroidery: It should get priority to execute automation. Nowadays embroidery machine can do some sewing functions to expedite production line. Embroidery machine can sew particular task at a time more quickly than sewing operators. For this, we need a pair of plastic frame and set up fabric layer into the plastic frame properly. Each embroidery head can handle a plastic frame and sew it quickly than sewing operators. Thus, it can execute some sewing operation to minimize sewing process from the main line.

4. Down filling: Some garments use down or feather item to protect from winter. Some modern equipment can speed up this task. Don’t set up down equipment in the separate room because it will take much time for handling. Please set up down equipment aside from running line. It will minimize handling time.

5. CAD and Pattern: Some modern device can minimize CAD and Pattern section functions.

6. ERP Software: Some ERP Software may help you to minimize total manpower from your organizations and give you an extra benefit to reduce extra paper works.

According to the above discussion, now we can understand that automation in the apparel industry is inevitable to increase productivity and prosperity. The more early we can launch automation in any apparel industry, the more early we can desire thousand of benefits.

You may like: IE department regular activities in apparel industry

Leave a Reply

You must be logged in to post a comment.