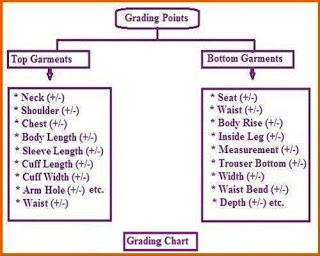

Introduction: Grading means step-wise increase or decrease of a master pattern piece to produce different sizes garment. Usually, grading modifies the overall size of a design to fit different age’s people. Pattern is an imperative part of any garment’s industry. It is one kind of size format which is needed to cut plenty of garment parts. To get accuracy, efficiency and high performance in garments industry must need skilled pattern team.

1. Basic pattern

4. Finish pattern.

Usually, pattern grading is done by pattern maker in pattern section. Pattern maker did it by following buyers spec sheet provided grading formula/measurement.

Pattern maker has to chase fashion designers guideline. Body structure of a human being is not similar to every region of this universe. Pattern grading usually depends on regional atmosphere like people’s physical structure, features, test, and habit etc. Suppose physical structure of Asian people may vary from Europe or the United States. If found any unclear point during pattern grading; pattern maker should check with the merchandiser to request the buyer to rectify those inequalities.

Those points are mentioned below:

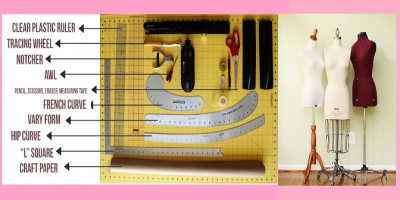

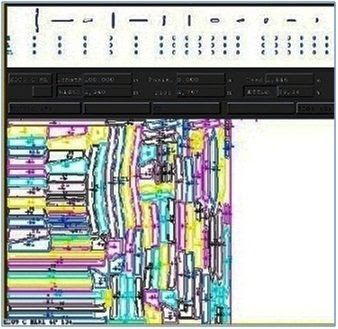

Marker making is a unique technique where to have to arrange all the pattern pieces of a garment item on the paper/fabric before cutting. This may be done by drawing the pattern pieces onto the fabric directly or by drawing the pattern pieces on a thin marker paper and then place the paper onto the fabric layer. Nowadays marker making task complete accomplished by the computerized machine to smooth the production process. By computerized marker making process, first need to open the basic pattern in computer. Then input desired grading ratio to get all size of pattern. Here normally use computer screen, keyboard, computerized plotter, marker paper and light pencil etc. to accomplish this task.

There are some techniques to minimize central fabric wastage outside of the marker like as minimize loose of fabric ends, minimize ends of ply loose, minimize purchase loose, minimize selvage loose. So, we can identify the marker like bellow. Marker is a thin paper which contains all necessary pattern pieces for all sizes of a particular style of garments in such a way that the fabric wastage would be least. The main purpose of the marker is to place it onto the fabric layer and provide right direction for cutting. Marker width is equal to the minimum fabric width, and its length depends on the number of pattern sizes that will be drawn or cutting table dimensions. The technique of constraining marker making is firstly big pattern is placed on the marker paper then comparatively small pattern are placed. Then shake the pattern on marker for placement in a short area. We can calculate marker efficiency by the following way.

Marker efficiency = (Patterns area in marker paper/Marker area) * 100

So, now we can realize marker making is very important element in apparel industry to achieve the highest usage of fabric item and for minimizing fabric wastage. By gaining better marker efficiency, we can reduce fabric wastage to cut our cost so that

our profit margin will be high.

The formula of Marker efficiency is shown below-

As we know, the fabric cost of a garment is required 50% (percent) of the total value. So, if 1% fabric cost is possible to save by efficient marker, this will increase the profit margin. So the proportion of marker making efficiency is very important to gain profit margin. The variable facts of marker making mentioned below-

d) Length of the marker

nature/type

Leave a Reply

You must be logged in to post a comment.