SOP for Cutting Knit, Fleece & Stretch fabrics

Before going to cut knit, fleece or any kind of stretch fabric garments industry have to follow some special techniques. There are some techniques which should be taken into consideration while doing cutting these stretch fabrics.

Before going to cut knit, fleece or any kind of stretch fabric garments industry have to follow some special techniques. There are some techniques which should be taken into consideration while doing cutting these stretch fabrics.

1) Fabric inspection is done by 4 point systems & 10% from the total order quantity covering all colors

2) Receiving of order sheet with sample/fabric shrinkage data/shade details and Fabric inspection report

3) Fabrics should receive shade wise from material department.

4) Every fabric roll should be unrolled for relaxation in gently. No force should be applied while unrolling.

5) Relaxed fabric should be stored in separate rack by attaching card with details information like Fabric Item, Shade Group, Batch, Lot, Color, Qty, relaxation starting date and Time

6) Separate Log book is to be maintained such as lot, cut date & Yardage

7) Relaxation process should be maintained at least 24 Hours from starting date and Time

8) Check bulk marker 100% Fabric laying as per shrinkage / shade, ensure no looseness/bias under each ply

9) Fabric laying height should not exceed more than 6 inches

10) Lay the marker and start bulk cut

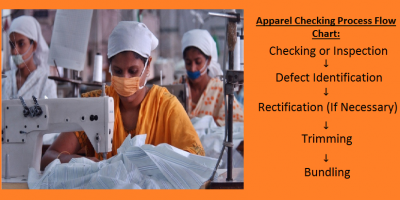

12) Cut panel inspection done by Q.A, correct size, fabric defects, cut panel accuracy (TOP, Middle and Bottom)

13) Cut panels Issue to production lines by lot and it should be distributed in trolley/bag

14) All cutting issue must be supply to floor at due time (W.I.P not available in cutting more than 2/3 days)

You may like: Basic points to measure a Jacket with power point slideshow

Leave a Reply

You must be logged in to post a comment.