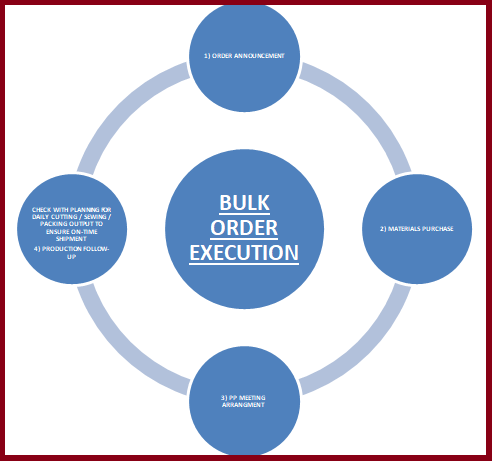

1// ORDER ANNOUNCEMENT

| RECEIVE PO SHEET & ORDER INQUIRY MAIL FROM BUYER OR CUSTOMER. |

| AFTER THAT HAVE TO WORK WITH PLANNING TO FIX EX FACTORY DATE BASED ON APPROX MATERIALS IN-HOUSE DATE |

| THEN INFORM EX FACTORY DATE TO CUSTOMER OR START CONVERSATION TO EXTEND EFD IF REQUIRE. |

| ONCE FIX ORDER CONFIRMATION, THEN NEED TO ISSUE ORDER INSTRUCTION WITH ALL DETAILS. AND INPUT ORDER DETAILS IN REGISTER BOOK. THEN PREPARE TNA CHART TO EXECUTE THE ORDER. |

| PLAN TO ISSUE PPS WITH ALL RELEVANT DOCUMENTS |

2// BULK MATERIALS PURCHASE

| ASSIGN MERCHANT SHOULD COMPILE ALL DETAIL INFORMATION, LIKE – APPROVE COSTING, INITIAL BOM, PRODUCTION OUTPUT, SAMPLE, SWATCH ALONG WITH OTHER MAIL CONFIRMATION |

| BASED ON INITIAL RECEIVE BOM FROM DEVELOPMENT TEAM HAS TO PREPARE FINAL MERCHANT BOM AFTER CROSS CHECK WITH SAMPLE. SHOULD PREPARE COLOR WISE BOM AS PER ORDER |

| · AFTER FINALIZE MERCHANT BOM HAVE TO PREPARE COMBINE MPR

· GET MGT APPROVAL BEFORE PRS · SHOULD SEND MPR TO STORE TO CHECK STOCK MATERIALS · MAKE PURCHASE SWATCH CARD FOR CHINA TEAM AND BULK TRIM CARD FOR BUYER · MAKE PRS FOR BULK & ALSO FOR PP |

| SIGNED PRS & MATERIALS SWATCH CARD SHOULD HANDOVER TO PURCHASE TEAM |

| PURCHASE TEAM WILL PREPARE MATERIALS TRACKING LIST BASED ON RLB# & MERCHANT SHOULD MONITOR SUPPLY CHAIN TRACKING FILE TO IN-HOUSE ALL MATERIAL ON-TIME. |

| IF REQUIRE ECO-FRIENDLY ITEMS THEN SHOULD GET IN-TOUCH WITH SUPPLY CHAIN TO RECEIVE 3RD PARTY / INTERNAL TEST REPORT FROM SUPPLIERS. CHECK WHETHER THE REPORT IS PASS OR FAIL. IF PASS THEN ASK FOR BULK PRODUCTION |

| AFTER IN-HOUSE ALL MATERIALS, STORE / QUALITY TEAM HAVE TO SUBMIT SHORT / DEFECT QTY REPORT QUICKLY. EXECUTION MERCHANT SHOULD ARRANGE REPLACEMENT MATERIALS THROUGH SUPPLY CHAIN ON PRIORITY BASIS. |

3// PP SAMPLE & PP MEETING ARRANGEMENT

| AS PER PLAN START PPS DEVELOPMENT. IMPLEMENT ALL REQUIREMENTS DURING PPS DEVELOPMENT. AFTER FINISH PP SAMPLE, EXECUTION MERCHANT, AS WELL AS QC PEOPLE, SHOULD CHECK PPS & DISPATCH.

INFORM CUSTOMER AND REQUEST FOR APPROVAL OF PPS |

| GET PREPARATION FOR PP MEETING. AFTER APPROVED PP SAMPLE, SHOULD ATTEND PP MEETING AND SHARE FOLLOWINGS FILES TO PRODUCTION & QUALITY GUYS.

· BOM · PP SAMPLE WITH COMMENTS · QUALITY CHECKING POINT · PACKING INSTRUCTION · APPROVED MOCK-UP · CM |

| ALONG WITH PP SAMPLE HAVE TO PREPARE ADDITIONAL SAMPLE FOR TESTING AND SHOULD ARRANGE 3RD PARTY TEST RESULT. |

| CHECK WITH PLANNING FOR DAILY CUTTING / SEWING / PACKING OUTPUT TO ENSURE ON-TIME SHIPMENT |

4// PRODUCTION FOLLOW-UP

| DURING BULK PRODUCTION SHOULD VISIT PRODUCTION LINE DAILY TO CHECK THE PRODUCT RANDOMLY. IF FOUND ANY QUALITY ISSUE THEN CALL A MEETING TO SOLVE THE ISSUES IMMEDIATELY. HAVE TO SEND DAILY PRODUCTION REPORT TO BUYER. |

| BEFORE START FINAL PACKING SHOULD PROVIDE NECESSARY GUIDE LINE TO PACKING TEAM TO AVOID ANY MISTAKE. PACKING TEAM WILL ATTACH ALL THE PACKING ITEM IN A SAMPLE THEN MERCHANT WILL CHECK AND CONFIRM IT BACK. ARRANGE SHIPPING SAMPLE BEFORE 10 DAYS OF EX-FACTORY. |

| PROVIDE NECESSARY INFORMATION TO COMMERCIAL TEAM TO ARRANGE SHIPMENT. AND CONFIRM GOODS EX-FACTORY TO BUYER THROUGH MAIL. |

| CLOSE THE ORDER AND CALCULATE PROFITABILITY. SHARE WITH ACCOUNTS & MANAGEMENT |

| AS PER PLAN, SHOULD ARRANGE FINAL INSPECTION THROUGH BUYER OR 3RD PARTY. |