Each buyer contains an individual logo or Icon or slogan to promote their brands. Usually, buyer wishes to have an attractive embroidery design or logo on their product. That design or logo represents buyers slogan. Let us discuss embroidery techniques, embroidery machinery, digitizing systems etc.

Each buyer contains an individual logo or Icon or slogan to promote their brands. Usually, buyer wishes to have an attractive embroidery design or logo on their product. That design or logo represents buyers slogan. Let us discuss embroidery techniques, embroidery machinery, digitizing systems etc.Digitizing is a combination of having fundamental skill in art management and computer process that takes design, photo, drawing or sketch and converts it into an embroidery design to decorate fabric or any other soft substance. That design is then programmed into computerized machines to make DST file to prepare the desired outcome of something, an age-old course of action of needle and thread called embroidery. It is more than an art and preferred still today.

Embroidery Design

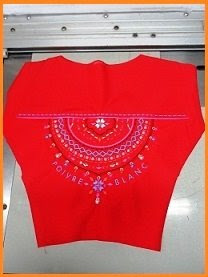

As we know, embroidery is an ornament of any garment, so it should be a good girl looking and durable. Sometimes buyer will provide embroidery design diskette, or sometimes they will give only embroidery sketch with the desired color combination. If buyer provides embroidery design diskette then its well and better but if provide only embroidery sketch with desire color combination that time we need to develop that embroidery design by local embroidery punching technician.

They have the vast knowledge to execute all designs in the house, even the most complicated designs. They are very proud of their long digitizing experience. Mainly the results of design are determined by the ability to do something well of a designer. Whether they are using old designs or digitizing from unusual rough drawing, they always try to provide the highest quality to meaningful the design. We called this process as embroidery digitizing or punching. Usually, the designer uses tremendous Wilcom software for making this type of design then it has to input into the embroidery machine by using floppy disk or pen drive. Then the design could be visualized on the attached monitor of embroidery machine.

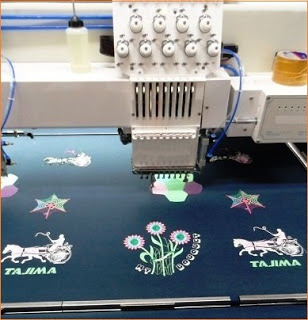

Multi-head embroidery machines are now more accessible and used. Embroidery machine contains automatic high-speed multi-function, which is a built-in data processing unit that able to sew multicolored embroidery.

Habitually, buyer will fix the embroidery design or logo size, position and color combination etc. during sample development. Moreover, we need to fix embroidery finishing, durability, after washing effect, measurement etc. before bulk production. Buyer should approve all embroidery design. Before placing bulk order buyer may want to know factories embroidery capability because it will affect production lead time. If factory does not have its self embroidery facility or not have secure embroidery source, it will affect production chain.

Nowadays, many apparel industries have to set up their embroidery unit to expedite smooth production, but some small garment factory does not have its own embroidery unit. That time they do their embroidery task from outside embroidery factory. It also a profitable business if someone wishes to set up only embroidery factory.

Tajima and Barudan are two renowned durable embroidery machine providers in this business. Tajima is perfect for light garments like jacket & pant, T-shirt, rain-wear etc. And Barudan is an excellent tool for some severe products like shoe, cap, backpack, and tent etc. The price of these appliances is very high compared with some other so-called china embroidery machine.

Currently, many China companies are supplying different kinds of embroidery device. What is much cheaper than Tajima or Barudan. Though China embroidery machine is cheap these machines performance quality, longevity, salvage value is not satisfactory than Tajima or Barudan. Only someone can choose these chines machines whenever their running capital is not enough. If someone wishes to gain a long time benefit, then they should choice Tajima or Barudan embroidery machine.

i) Number of heads of that embroidery machine ii) Number of needles (how many colors it can do at a time) iii) Embroidery floor space and demand of incoming bulk order.

If we purchase an embroidery device considering tiny area or capability, then we cannot be able to do embroidery task smoothly or perfectly. Especially if girls costume or kid’s wearer does not have a different decorative duty, they will lose interest to purchase those products. For this reason, the designer always applies much attractive design on their products to appeal to their targeted consumers. These designs played a vital role to increase ready-made garments demand among us. And nowadays embroidery industries are doing this ornamental task very quickly by automated multi-headed computerized machine. Export of ready-made clothing is growing every year with the help of embroidery industries.

It is remarkable that if a product FOB value is $10, then the contribution of print and embroidery is, at least, $1.5. That means to print, and embroidery does not exist; this can be sold by $8.5. Embroidery sector is overgrowing by amplifying beautification of garments. It also adds additional value-add service that creates employment. So, we can quickly realize the importance and value-add service of these supporting industry in apparel industry what is inevitable.

You may like: Different types of embroidery stitches and their features

Leave a Reply

You must be logged in to post a comment.