Fabric manufacturer always gives their best effort to produce their goods, but some defects may exist on their products despite their level best attempts. End of the fabric manufacturing process some significant errors may appear to the fabric supplier or garments producers. Usually, different sort of fabric defects like pinholes, back fabric seam impression, broken color pattern, color out, color smears, drop stitching, birds eye, bias and bowing, fold mark, dye coating spot, dent mark, dye streak in printing, hole, jerk-in, knots, mixed yarn, crease mark, mottled, needle line, open reed, press off etc. may found onto the fabric layer during fabric inspection. In order to avoid fabric rejection, mills have to produce fabrics with high quality continuously by enhancing monitoring and modernizing production process simultaneously.

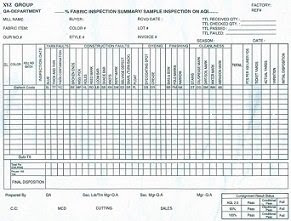

Generally, after received bulk fabric item from suppliers, material control department send this fabric item to the Quality department for their checking. Quality control manager should provide sufficient training to their inspectors to identify fabric defects and their root causes. They have to supply actual examples or photographs of both significant and minor flaws. Moreover, they have to provide a list of defects and explanations and simplify the language and the judgments used in making visual fabric evaluations. During woven fabric quality checking, they classified those defects like below:

|

|

||

|

Thin Place

|

Where the area of weft yarn is smaller in diameter than normal to the fabric. Often caused by the filling yarn breaking and the loom continuing to run until the operator notices the problem. (Severity: Major or minor)

|

||

|

Thick place

|

Where the location of weft yarn greater in diameter than normal to the fabric. (Severity: Major or minor)

|

||

|

Broken end

|

Yarn broken in a warp direction in woven fabric.

|

||

|

Hole

|

Any has broken yarns to form a hole. (Severity: Minor but in severe case major)

|

||

|

Reed Mark

|

A defect resulting from a twisted reed wire, characterized by a fine-lined thin place in the warp directions. (Severity: Major)

|

||

|

Reed Stark

|

A warp-wise streak caused by a broken reed in weaving. (Severity: Major)

|

||

|

Tight end

|

A warp yarn in an abnormal restriction than the adjacent standard yarns

|

||

|

Shade bar

|

A change in shade within a short duration across the width of the fabric.

|

||

|

Burl Mark

|

A slub or yarn knot being viewed in a piece of fabric. This is often removed by a “burling tool.” (Severity: Major)

|

||

|

Slub

|

A little abnormal thick place in yarn. Usually caused by an extra piece of the yarn that is woven into the fabric. It can also be caused by fly waste being spun in yarn in the spinning process. (Severity: Major or minor)

|

||

|

Dropped Pick

|

Missing weft yarn. Yarn is broken in a weft direction in woven fabric. Caused by the filling insertion mechanism on a shuttle-less loom not holding the filling yarn, creating the filling to be woven without tension. (Severity: Major)

|

||

|

Stop Mark

|

Inconsistent of yarn tension while a loom is stopped, the yarn elongates under tension, when loom starts again, the slack is woven into the fabric. (Severity: Major or minor)

|

||

|

Soiled Filling/End

|

A weft yarn soiled by dirt or grease. Dirty, oil looking spots on the warp or filling yarns or on package dyed yarn. (Severity: Major)

|

||

|

Smash

|

Caused by a number of ruptured warp or filling yarns or on package dyed yarn. (Severity: Major)

|

||

|

Mixed Filling

|

Caused by bobbin of lightweight yarn or different fiber blend used in filling. Will appear as a distinct shade change. (Severity: Major)

|

||

|

Mixed Ends (Yarn)

|

Yarn of a different fiber blend used on the warp frame, resulting in a streak in the fabric. (Severity: Major)

|

||

|

Knots

|

Two or more ends of yarn tied together. Caused by tying spools of yarn together. (Severity: Minor but in severe case major)

|

||

|

Jerk-in

|

An extra weft yarn jerked by the shuttle into the fabric along with a correct pick of weft yarn. The defect will appear at the selvage. (Severity: Major or minor depending on how close the patterns are cut to the selvage)

|

||

|

Harness/Loom Bar

|

Caused by the harness straps breaking on a conventional loom. There will be a particular pattern change in the weave. A change in the shade across the full width of fabric. (Severity: Major)

|

||

|

FLY

|

Waster fibers of different color are woven into the fabric as contamination. Usually caused by the spinning process, small fibers spun into the yarn of another stock. Often caused by lack of precaution to prevent contamination. (Severity: Minor but in severe case major)

|

||

|

End out

|

A missing warp yarn. Caused by yarn breaking and loom continuing to run. The defect will appear as a thin line. (Severity: Major)

|

||

|

Dye/coating spot

|

Caused by dyeing or coating layer onto the fabric. (Severity: Major)

|

||

|

Drawback

|

Caused by excessive loom tension gradually applied by some abnormal restriction. When the restriction is removed, the excess slack is woven into the fabric. Ends are usually broken. (Severity: Major)

|

You will get that file from my google drive link. Please hit the link to download your desired file.

Leave a Reply

You must be logged in to post a comment.