The followings are some basic principles for day to day improvement especially perform as a quality leader.

* Know your business and its volume to be intimate with the details. It will make an inspiration to move faster.

* Be accountable and hold your team’s accountability. TQM (Total quality management) is inevitable in this regard.

* Focus on issues, not on people and keep away any personal relation during decision making. The issues wherever comes from, please try to hit there and keep it under control.

* The customer is the edit point. So, we have to realize buyer’s tendency and obey their direction point by point.

*

Be professional in everything while you execute the highest label and be disciplined in your reporting.

* Have a sense of urgency. As you know, shipment schedule is almost fixed for finished goods toward buyer’s destination. So, we should apply good sense to hit delivery schedule.

* We are one global team – we will win by working as a team. It’s a key point to work together. We not only try to accomplish our task perfectly but also focus on to improve others operating procedure.

* Escalate issues immediately – escalation is not only just reporting but also should sit together to find a solution or diagnosis to make a path.

* Do not

compromise with quality or service. It’s one of the most important key points to work as a quality leader. There is no option to negotiate with product quality or service.

* Always identify the root causes of any issue and think for long-term solutions to avoid the same incident occur in the future.

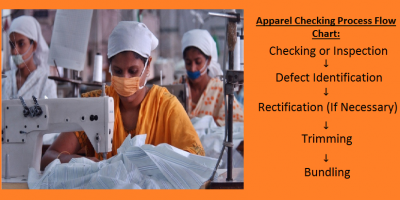

Additionally, they have to be aware of handling day to day regular production and should maintain the following tricks for betterment:

1) Print/Embroidery panel have to be inspected 100% by maintaining proper report and checklist.

2) Print/

Embroidery panel apparently check by QC with approved PP sample, approved pattern, and final worksheet.

3) Concern pattern maker delivers their pattern with their signature before issuing to bulk production.

4) Machine tension needs to check at least two times each day and keep a record.

5) It is not their job to find who is wrong; their main duty will be how we to solve and fix the problem quickly. Hence, they have to arrange a meeting to know personal responsibility, line status, season, order quantity, inspected quantity, defect quantity, first delivery date, color wise break down and make action plan against any complicated issue for better implementation.6) At the initial stage of any new production, at least, ten pieces garments must be evaluated by floor quality in charge and report to Q.A Manager. If necessary, Q.A manager will review it and provided us a guideline for improvement.

6) At the initial stage of any new production, at least, ten pieces garments must be evaluated by floor quality in charge and report to Q.A Manager. If necessary, Q.A manager will review it and provided us a guideline for improvement.

7) Whenever any problem arises, it is not sufficient to inform verbally or make a phone call only; we must send mail or report it to concern people in written to come to the needle point and fix the problem quickly.

8) All concern people must attend in PP Meeting including material department, pattern maker, cutting Q.C,

sewing technician and maintenance, finishing before step into bulk production.

9) All buyers have particular AQL (acceptable quality level) which is a criterion to evaluate RMG. Quality leader has to understand AQL and strictly monitor the inferior are following guideline.

10) The worlds are changing rapidly, and the techniques of garments production are altering too fast. So, quality leaders have to enhance their knowledge to cope up with working environment by training and reading buyers SOP, factory compliance, AQL (acceptable quality level), TQM (Total quality management), ASQC (American Society for Quality Control), and AAMA (American Apparel Manufacturers).

Leave a Reply

You must be logged in to post a comment.