Introduction: It is one of the essential steps before cutting arrangement during large quantity of garments production. Some factors should consider before marker making such as pattern of the garment, fabric width, garments size ration, fabric fault and cutting table width, length etc. It is mention-able that bulk quantities of garment cannot be cut without marker and marker efficiency is always depending on some factors what already explained in another article.

What is Marker?

Marker is an ultra thin paper where need to gather all the necessary pattern pieces for all sizes of a particular style of a garments item. The main reason to make marker is to reduce fabric wastage that will ultimately reduce total cost of a garment item. Another reason of marker is to place it onto the fabric layer and provide right direction for cutting. We have got a prior idea regarding fabric consumption through marker making during sample development, and it should make just before start cutting. Marker making is a common process before placing fabric order to the suppliers. All the pattern pieces need to be set very carefully in the marker to reduce fabric wastage. Fabric width is greater than or equal to the marker width to make easy cutting task.

Types of marker:

Four kinds of marker usually used in bulk production such as:

1. Shading marker, 2. Non-shading marker, 3. Group marker, and 4. one or two-way marker.

Different procedures of marker making:

There are two different methods usually used for marker making in the apparel industry.

i. Manual method.

ii. Computerized method.

i.

Manual method:

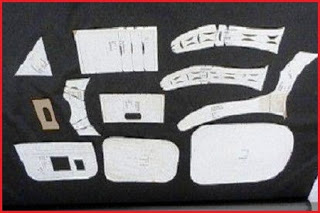

It is one of the oldest, traditional and typical method used for marker making in the garments industry. In these processes, all pattern pieces made by pattern maker manually and after that fabric needs to spread on cutting table then put all pattern pieces chronologically on the fabric layer. Then mark it with chalk, pencil or pen. After that, the cutter will cut the fabric by following chalk mark. Regret to say that production cost and lose percentage of fabric is always more than the computerized method but the output is nothing than expectation. This process needs more time,

practice and experience but efficiency and accuracy are not satisfactory. Usually, small factories may follow this process considering high set up cost of modern computerized equipment. It is generally a slower method and never been copied as and when requires.

Two ways is preferable to do manual method:

A) Full-size Marker: Marker planning with the full-size pattern. Usually, it is made for production purpose. All the patterns are in full dimension to put on the fabric layer and then those patterns are marked with chalk by changing different directions to minimize fabric expenditure. Please set the marker paper carefully and congest it gently so that they do not put out of place.

B) Miniature type Marker: Marker planning with minimized pattern. Usually, it is made to plan or schedule and learns or study i.e. for planning and learning purposes. By this process, full sized patterns need to be reduced as much as possible to visualize a large pattern in miniature form.

ii.

Computerized method:

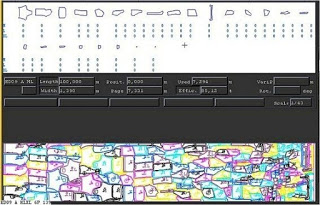

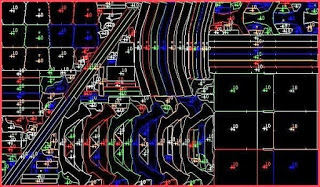

Usually,

pattern maker is liable to design all garment pieces accurately then send it to marker man to make an electronic marker. Marker man amalgamates all clothing pieces and decorates efficiently to minimize fabric lose. Once marker is ready to work, it needs to be print out through a plotter machine. Then the marker paper can be placed on the fabric layer and use for fabric cutting. During marker making, fabric length and width, cutting table size must be taken into consideration to minimize the wastage. Computerized marker paper directly set up on fabric layer. Fabric needs to cut according to marking line.

Two ways is preferable for computerized marker:

a) Automatic marker making:

It is one of the easiest and efficient processes of marker making. Several integrated software’s like GGT, Lectra, Gemini are useful to make a computerized marker. Just only need two minutes to make an automatic marker. The computer makes the marker itself according to the command given by the operator. It is more competent and useful than interactive marker making method.

2. Interactive method:

It is another marker making process where marker man decorates all the pattern pieces directly by applying their merit. By this process, all the pattern pieces are placed at the top of the screen of a computer in the miniature form. Then marker man can drag and drape into the pre- determined place through mouse pointer. Interactive marker making method mainly used to make shading marker or if found any serious fault in fabric. But it has never been alternative than automatic marker as comparatively less efficient.

Merits and demerits of the computerized method are given bellow comparing with the manual method.

Merits

1) It can cut sharp corners & circular patterns with the notch accurate.

2) For diminishing fabric wastage

3) To reduce production cost

4) To reduce labor cost

5) To reduce time and more productivity

6) Marker can be prepared quickly than manual method

7) Marker can be kept a long time in computerized system with high security

9) Though Initial investment is high but we should consider long time rate of return.

10) More appropriate for huge range production than the manual method.

11) Marker effectiveness and accuracy is higher than a manual system.

12) If require, marker could be print out and can send the marker to the buyer along with the sample for their review.

13) Grading of the pattern could be done automatically.

Demerits

1) The more skilled efficient operator is needed than manual.

2) Primary investment is higher than manual.

3) Need much money and technical support for maintenance.

Buyer always relies on computerized method due to its various facilities. Moreover, it will attract buyers focus and increase their satisfaction too with its modern facilities. However, everything has its optimistic and unenthusiastic effects. But if we think of long time goal, the merits of the computerized marker are more than the manual. It will increase efficiency, accuracy, production capacity of any factory. It will save valuable time and minimize fabric wastage what save money too. The more fabric saving means possibility of more profit margin. You are requested to click my google drive link to get a fantastic guideline regarding pattern making process. Please hit the link to download your desired file.

ii. Computerized method:

ii. Computerized method: 8) Neat and clean working environment than the manual method.

8) Neat and clean working environment than the manual method.

Leave a Reply

You must be logged in to post a comment.