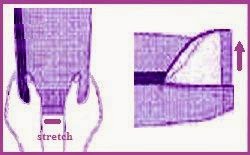

The finish goods what we purchased from the market is the results of many people’s efforts. Generally, designer, material provider, operator, and producer are directly involved in generating a garment. It is mention-able that customer will never purchase quality less product from the market. But it is also too tough to keep product quality when it produced in bulk production. To ensure product quality, Q.A guy has to scrutiny every point with full concentration.

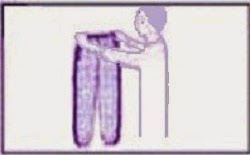

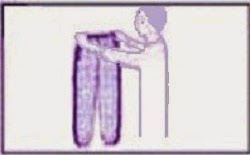

1. Check appearance by holding garment (pant) at the waist. Examine front and back. Make symmetry control by folding the garment.

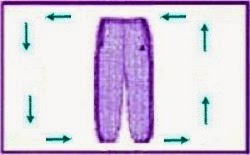

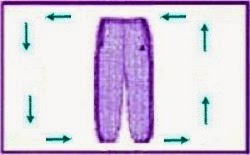

2. Lie garment flat (pant) on the audit table. Check for style details, examine front and back embroidery design/print or heat seal design which exist in the garment.

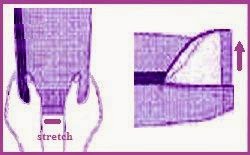

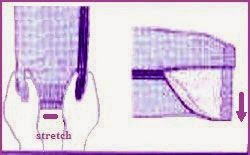

6. Lay garment flat on the audit table with front rise towards auditor (Inseam to Inseam). Stretch left side seam to full extent. Inspect left side seam including pockets if applicable. In case of 3 stripes stitching inspects inside well.

7. Stretch left leg opening to full extent, inspect left leg opening. If having zipper, unzip and inspect.

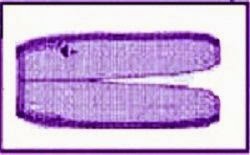

10. Stretch inseam in four parts to full extent. Inspect total inseam.

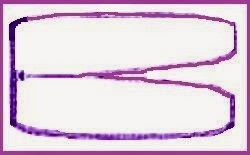

11. Fold left leg forward (to original position). Turn pant over back rise to auditor (inseam to inseam). Stretch right side seam to full extent. Inspect right side seam, including side pockets if applicable. In case of 3 stripes stitching inspects inside well.

12. Stretch right leg opening to full extent, inspect right leg opening. If having zipper, unzip and inspect.

13. Turn garment inside out. Lie garment flat on audit table. Make sure any unchecked seam on inside.

Leave a Reply

You must be logged in to post a comment.