Line efficiency plays an important role to produce target garments production. Line efficiency shows production line daily achievement and performance. Measuring the efficiency of a production line is very important for a garments factory to make it profitable. For the comparative study of the sewing line performance, and to know the achievement of a garment factory, we measure production line efficiency. Normally it’s done by industrial engineers. Today we will try to show you the estimation process of line efficiency of a garment industry.

Production Line Efficiency Calculation Parameter

There are several parameters exist to calculate the daily efficiency of a particular production line. Then you need to collect the following information from the line supervisor or IE department to measure line efficiency.

1. Number of operators – How many operators worked in the line in a day.

2. Production in pieces – How many pieces are produced or total line output at the end of the day.

3. Garment SAM – What is the exact standard allowed minute of the running garment item.

4. Working hours How many hours the line ran in a day or how many hours each of the operators worked (Count regular and overtime hours).

Once collect these required information from the IE department then you may calculate line efficiency by using the following information –

A) All present line operators total minutes:

Multiply the number of operators by daily working hours and convert total hours into total minutes (multiplying by 60).

B) Total minutes produced by the line:

To find out the total required minutes, just multiply daily production pieces by garment SAM

Now, we will try to calculate line efficiency by using the following formula:

Line efficiency (in percentage) = (Total minutes produced by the line *100) / (Total minutes attended by all operators)

Suppose,

35 operators worked in a line for 10 hours in Rider leather bags factory. They can deliver 180 pieces bags daily and the Standard Allowed Minutes (SAM) of that item is about 30.50 minutes.

Here,

Total minutes produced = (180 x 30.50) = 5490 minutes

Total minutes attended = (35 operator x 10 hours x 60) = 21000 minutes

Efficiency% = (5490 x100)/21000 % = 26.142%

So, the line’s efficiency of the mentioned bag production stands at 26.14%

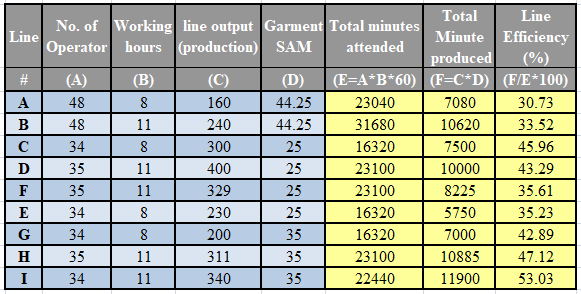

You are requested to follow the below table to more clear. Please count the header row of the table for data calculation formula.

Let’s calculate several production line efficiency of a garment factory.

You may like How to Calculate Sewing Line Capacity of an Apparel Industry?