We know garment manufacturing sector is a production base chain process. So it is very important to know each day production capacity of a garment factory for buyers as well as to factory management to take right decision. Thus production capacity estimation is a common issue for all related parties. It plays an important factor to the buyer in selecting the right vendor for their orders. It is also very significant factor for production planners. It is important in the garments manufacturing sector to know their each day production capacity. So, today we will try to show you how to calculate each day production capacity of a garment factory.

Production Capacity:

Standard Allowed Minute (SAM), machine (hour) capacity and line efficiency are directly involved in calculating the production capacity of a garment factory to produce any garment item. Industrial engineering department should measure cutting room capacity, finishing room capacity, and washing capacity to get the exact production capacity of a garment factory.

Production Capacity Calculation Method of a Garment Factory:

IE department has to focus on the following points to find out accurate production capacity:

- Factory machine hour capacity

- Standard Allowed Minute SAM

- Factory Average Line efficiency

Now the question is how to find out factory machine hour capacity.

Ans: Machine hour capacity = number of usable machines x working hours per day.

To get factory machine (hr) first find out how many machines factory has and factory per day working hours.

Suppose,

Total number of machines = 300

Shift hours per day = 10

So, total factory machine capacity (in hours) = 300*10 hours = 3000 hours

How to find out SAM?

Ans: Hours to produce one product = number of products produced in a day/hours of operation.

SAM means number of particular product produce in day/hours. IE department may help you to get this data. First, get the product list that the factory produces and then get standard allowed minutes (SAM) of all products from work-study engineers. Suppose you are producing a shirt and its SAM is 25 minutes.

How to find out Factory Average Line efficiency?

Ans: You have to consider factory working hours, number of operators, garment SAM, and production in pieces to get line efficiency. Better this data should be collected from the IE department. Suppose the average line efficiency is 60%.

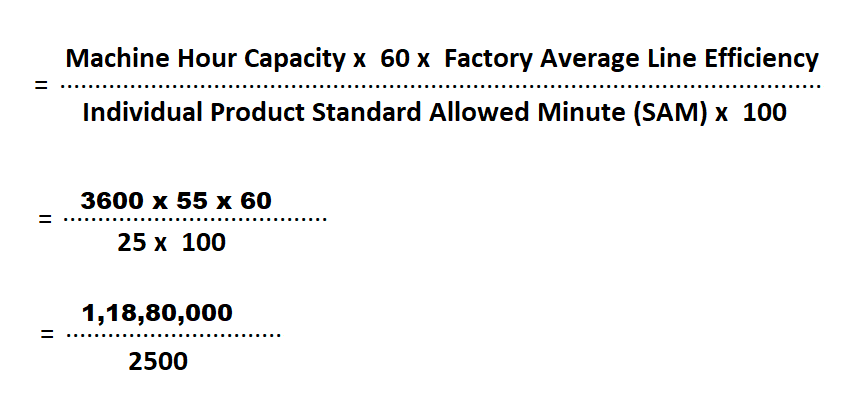

Now, someone can easily calculate the production capacity of a garment factory by using the following formula.

Example:

Suppose, New Era Fashion Ltd. has 12 sewing lines, each sewing line has 30 sewing machines. Their basic production item is Kids Jacket. Factory working hour per day is 10. (Where machine-hr capacity is 3600hrs and average line efficiency is 55%).

So, find out the production capacity of that factory.

Solution:

Here,

Machine (hr) capacity per day= 3600hrs,

Average line efficiency = 55%,

Standard allowed minute (SAM) for kids jacket= 25

So,

Productions capacity (Pcs),

= 4752pcs

So, the garment production capacity of the above factory is 4,752 pcs per day.

N.B: Estimation process of production capacity is not only usable for garments industry but also use for any other manufacturing plant. It’s easy and simple. You can use this formula by changing figure to get optimum results.