Big shears are known as hand scissors, and it’s a common cutting tool in home or tailoring house. Garment industry has to use this manual tool for several purposes. It mainly used to cut few fabric plies. It can’t cut more fabric plies at a time. It consists of two sharp blades. Two types of big scissors are available in the market for the right and left-hand users.

A knife having the shape of an endless sharp thin belt running over a set of pulleys and used for splitting hides into two or more plies for cutting many thicknesses of cloth. Much more accurate cut smaller part, suitable for cutting sharp corners like piping, loops etc. Not suitable for large part cutting, more fabric wastage as block piece of fabric is required but possible to cut 90% angles of the lay. Air blower helps to reduce the fabric weight and puffiness which increases smooth movement of the fabric.

Most of the garments manufacturers prefer this device. It is an ideal cutting tool for garment industry because it is portable, versatile and cheaper than any other cutting options. Straight knives are appropriate for cutting curve lines in high lies because the blade can strike all the plies simultaneously at the same time.

4) Auto Cutting:

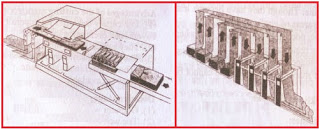

4) Auto Cutting:It is a modern edition of table cutting. A computerized auto cutting machine adds with the cutting table to smooth its operation. By this process, first fabric layer lay down on a conventional cutting table by men or spreader and after that computerized auto cutting machine feeds the fabric layers to start cutting according to the computerized marker. This machine drags the fabric layer from conventional cutting table to accomplish the cutting process. This process no needs additional marker paper, but marker paper set onto fabric layer to recognize fabric cut panels during bundling. Only a few operators require just handle the whole process. Auto Cutting device is very straightforward and easy to use. It will reduce fabric lose, manpower and increase productivity. If someone wishes to add auto cutting process in their factory, they just need to spend some extra money to apply this process. Though installation of this process is high but the return of long time benefit should consider. Auto Cutting device is totally safe and friendly for the operators.

Die cutting is another option in cutting operation. Die-cutting is a process where pressing the sharp portable rigid blade onto the laid fabric. The die is a sharp shape of the pattern border including notches by bending the strip into the form required and welding the joint. It cannot be sharpened and must be replaced when got damage. Which garment exist small critical part and very difficult to use a normal cutting tool or other cutting option that time we can use die cut to accurate the sharp corners & circular patterns.

Die cutting method mainly used for embroidery applique, shoulder pads, cap, shoe & backpack items cutting to get a high standard of accuracy but only appropriate to the situations where huge quantities of the same pattern will be cut. This process is perfect for cutting sharp corners and circular patterns but not suitable for larger parts. It may increase production cost, cutting time and fabric wastage as used block pieces. Operators should be more careful to handle this device because a heavy metal bar creates 20-ton pressure during cutting.

Some machine manufacturers have designed fully automatic die cutting lines for tubular fabrics. These systems can feed multiple lengths of tubular fabrics on the table of the machine for cutting by the die. After cutting, the cut panels are automatically ejected for bundling. A single die can cut center front, center back, and sleeves of a T-shirt. Such type of machine can cut around 1,200 pieces t-shirts per hour.

These are specialized tools used to cut rib or rolls of strips from knitted tubular fabrics. They can also cut strips from woven, vinyl or other fabrics. Some machines are so sophisticated to be able to accurately measure and cut fabrics, such as tapes, ribbons, strapping’s, elastics etc. Most of the factories use them for rib cutting in the knit garment factories. There are machines which are quite simple.

These are specialized tools used to cut rib or rolls of strips from knitted tubular fabrics. They can also cut strips from woven, vinyl or other fabrics. Some machines are so sophisticated to be able to accurately measure and cut fabrics, such as tapes, ribbons, strapping’s, elastics etc. Most of the factories use them for rib cutting in the knit garment factories. There are machines which are quite simple.There are other types which are automatic and with computer control with multiple speeds and are equipped with winding and tension control devices. Figures show rib cutting machines used in the knit garment industries for producing ribs for binding tapes for T-shirts, panties, briefs etc.

You may like: Fabric Cutting devices using in apparel industry- 2nd part

Leave a Reply

You must be logged in to post a comment.