Cutting department is the feeding section of any garments industry. The garments sector is a place where there is no excuse for mistakes in fabric cutting. The responsibility of a cutting in-charge in the garments sector is very important. Thus, the entire responsibility of fabric cutting depends on a cutting in-charge. If there is a mistake in fabric cutting, all the responsibility falls on the cutting in-charge. So the cutting in-charge always has to be careful. The amount of error in the cutting section can be reduced by properly allocating responsibilities and providing direction between subordinates. Usually, after working in the cutting section for 10-15 years, he is promoted as the cutting in-charge. Through this post, we will know about the responsibility of cutting in-charge.

The responsibility of cutting in-charge is immense. Managing the work properly, starting from the supply of the work to know the quantity of the order of the buyer and whether the cloth has been supplied as per the consumption, whether there is any shortage in making the garments, the superiors should be informed. How to do a job can be easily solved by a small number of workers, how much cloth is needed to supervise such work falls under the responsibility of the cutting in-charge.

A cutting in-charge needs to have the skills to operate a cutting machine. There is no need to make patterns regularly, but many cutting masters know how to make patterns manually. However, you should know pattern making process to become a cutting master. It is the sole duty of the cutting in-charge to check the marker before cutting. It is the responsibility of the cutting in-charge to keep a proper account of the fabric by layout according to the ratio and assort and show the work technique to everyone in the cutting department.

Responsibilities of cutting in-charge:

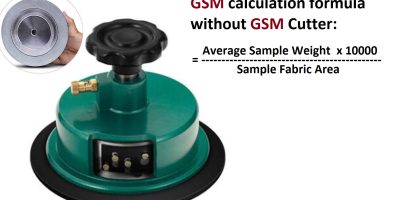

1) Assist in the work of cutting managers. Inform the manager in advance about the weekly schedule. Pre-cutting procedure maintain to follow up properly (Such as dia, GSM, fabric relaxation, shade separation & shrinkage test etc).

2) Provide all types of reports to the Planning Department and follow their instructions. Keep knowledge about the production schedule. Make the master cutting plan as per production plan.

3) Check the quantity of the order from the merchandising department and the quantity of fabric according to the marker ratio. Plan wise fabrics receive monitoring. If arise over consumption problem then talk with the authorize merchandiser and CAD.

4) Establish a good relationship between top-level management and mid-level management. Provide all kinds of reports to them.

5) Arrange to keep the swing section running continuously. Keep a good eye on the cutting flow on the production floor. As per plan provide print and embroidery support properly.

6) Check the mini marker and ensure marker efficiency according to marker ratio & Assortment, actual fabric dia, GSM.

7) Provide regular training to its subordinates. Make sure that the working environment of the line is not disturbed under any circumstances.

8) Once fabric receive, check it through cutting QC (check if there is any problem of rejection, hole, or dyeing in the fabric). Maintain the minimum lay height according to fabric types.

9) Plan the daily work at the beginning of the day according to the importance of the buyer and the order and determine how much clothes will be needed, how much marking will be done? Input given as per line loading plan.

10) Training his subordinates on how to use the cutting machine in the most efficient way and how well the fabric can be laid on the table.

11) Coordinate and work with cutting QC. Lay the fabric well on the table according to the shade bend. Be careful not to waste too much. Ensure fabric relax according to fabric types.

12) Not avoiding any responsibility for any kind of damage (material, machine, and equipment).

13) Conduct the activities of all cutting operators and assistant cutting operators and marker men working on the floor to keep the production process active as per the instructions of the Technical Manager and Production Manager.

14) Submit daily work reports to the Technical Manager and Production Manager. Ensure the daily productivity of the cutting section.

15) Use fabric efficiently and cut as less fabric as possible and provide shortlists to relevant sections quickly.

16) If there is any problem that arises in cutting and if there is any problem to solve it, should take the help of the PM or Factory Manager immediately.

17) Special care of dummy, size set and trial cutting. Get the QC approval for the sample & trial cutting?

18) When fabric consumption saves then talk to dying responsible to stop it from knitting stage.

19) Urgent shipment special follow up and hourly cutting monitoring. Last day target and achievement check.

20) Special care to reduce overtime. Compliance, 5S, quality, RQS and follow the company rules and regulations strictly.

You may like: Duties and responsibilities of a cutter in cutting section