What is BOM?

Bill of material is abbreviated as BOM. It is a list of raw materials. Bunch of raw materials that are required to be sourced for producing a particular garments item is called BOM. Merchandisers should confirm that all of the materials are sourced from the suitable place at competitive price. Thus, they have to prepare it from the sample development stage. And revise it constantly before starting the garments production to ensure smooth delivery. Garment merchandisers should be aware of shipment date of the garment before preparing the bill of material,

In the readymade apparel industry, it is the most common scenario that merchandiser has to create BOM before starting sample development. BOM has to be revised several times before bulk production. BOM is normally prepared by the factory merchandiser or production merchandiser. After that, it is approved by the merchandising manager or any other responsible person from the factory owner and handed over to the purchasing or procurement department to purchase and in-house all the required goods before bulk production.

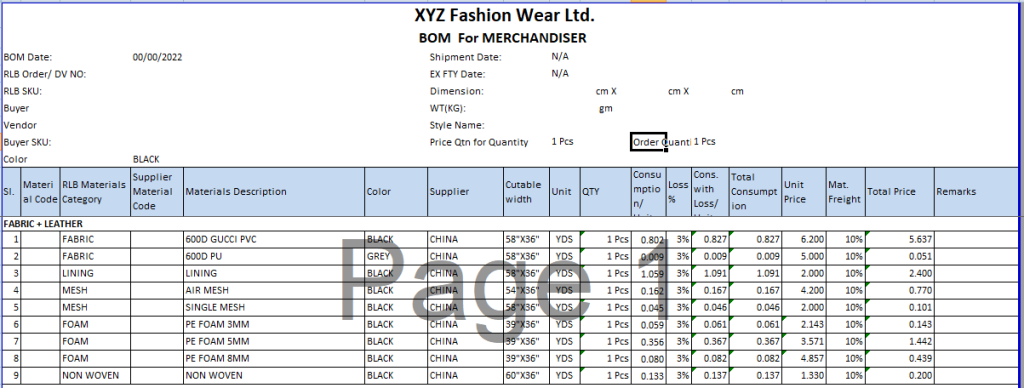

BOM Information:

Factory merchandiser has to make the BOM very carefully because it is a written document for all the related parties in the garment industry. A silly mistake may bring a big hassle. Thus merchandiser has to check it frequently. Otherwise wrong material issues, shortage material issues may arise regularly during garment production. Bill of material contains the following information:

- The person name, who is responsible for sourcing

- Materials Description

- List of all fabric, trims, accessories, thread, printing, embroidery, and packaging items

- Actual materials consumption

- Consumption with loss percentage

- Style name, sample image, buyer name, buyer SKU & season

- Shipment date, Ex-factory date

- Supplier name with country of origin

- Raw material price

- The projected cost per item

- Material price with freight cost

- Product Quality

- Quantity required for

- Product specification Supplier Material Code

- Size or length (buttons, zippers)

- The total cost of raw material

- Raw material color name or color code

- Sourcing date

- Cuttable Width

- Product unit (Yds, Pc, Mtr)

- Include mold cost, testing cost, overhead, and CM cost

- Margin with FOB price

BOM Preparation Method in the Garment Industry:

We can divide the BOM into four parts that are (fabric), (trims/accessories), (thread, printing & embroidery, and packaging items. Bill of material-making process is very important in the garment business for price quotation. So BOM making is a very sensitive issue to get the final order. Usually, factory merchandiser or development team receives the original sample or detailed information of the product (product quantity, color, size, style, etc.) from the buyer or buying house. Once the required information is in hand then they start to make bill of material by inputting all data in a specific format that is call BOM. It is a common practice that the factory merchandiser or development team has to deliver a complete bill of materials to the procurement team to source all raw materials from the best place with competitive price according to the garments item. Otherwise, they may mix up all.

Bill of Materials or BOM Format Followed in Apparel Industry:

Following bill of materials format attached for your reference which usually used in the garment industry to compile all the materials in one sheet.

You may like Know the formula to find out how many kg is equal to 1 yard of cloth?