Polybags are a popular type of thin, flexible, plastic packaging item. Poly bags are made by extruding and molding polyethylene or similar plastic compounds into the desired shape and size. Polypropylene (PP) is a common poly bag material that belongs to its own category. Polybags, also known as polyethylene bags, provide an economical shipping choice that protects against dirt, moisture, and tampering. Polyethylene bags are heavy-duty, durable bags that easily endure rough handling without breaking or tearing.

Polymer is the main substances of Polybags. Its unit is pound. It can be PP, PE, and LDPE, etc. Polybag is a mandatory item for shipment. Garment merchandiser should know polybag costing. It’s not very tough what we think. Today we are going to show you the polybag costing calculation method.

Poly Bag Costing Calculation Method:

A garments merchandiser should know the following information first before going to calculate poly bag costing:

- Polybag length

- Polybag width

- Poly bag thickness

- Flap width

- Number of print

- Current Market Rate of polymer

Important Tips*

- First calculate poly bag consumption

- Then calculate required polymer quantity to produce those poly bags.

- A garment merchandiser can easily calculate poly bag costing by multiplying poly bag consumption with polymer rate.

To clear all the confusion please refers to below example of poly bags costing.

Example:

Suppose, a merchandiser has to collect 800 poly bag for “TNF” buyer.

Poly bag length – 32”

Poly bag width- 18”

Poly bag thickness – 150gauge

½ flap of the poly bag- 5”

Rate of LDPE polymer- $0.42 per pound.

Let’s calculate poly bags costing based on the above information.

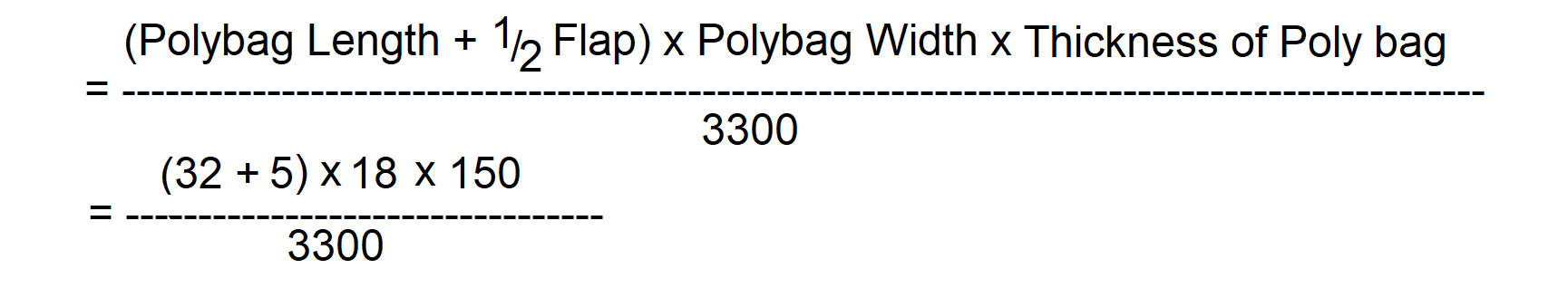

Now we can find out poly consumption in accordance with the presented data.

Poly bag consumption formula for 800pcs in kg),

= 30.27 kg per 800pcs ply bag.

= 30.27 kg per 800pcs ply bag.

So, for 800pcs poly bag, LDPE polymer needed 30.27kg.

And,

For 1pc poly bag, LDPE polymer needed,

= (30.27/800) kg= 0.03kg= (0.03 × 2.20) lbs= 0.066 lbs [1 kg = 2.20 lbs]

So, final cost of 1-piece poly bag will be ($),

= Polymer needed for 1pc poly bag × Polymer cost per pound (lb)

= 0.066 × 0.42

= 0.027

So, the cost of 1pc poly bag is $0.027

And,

Cost of 1000pcs poly bag,

= $(800 × 0.027) = $21.6

N.B: 3300 is a factor used for quick calculation which means per cubic inch of poly film in grams. This factor is applicable to LDPE only]

You may like: How to Calculate Poly Bag Costing?