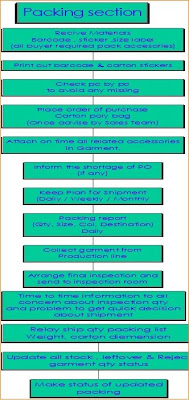

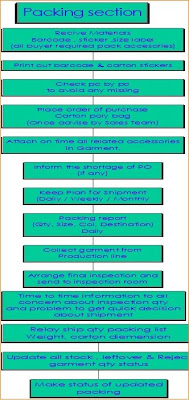

Finishing section is another essential part of any apparel industry. Usually, finishing guy will attach hang tags, bar-code sticker, price sticker etc. Properly with the apparel items according to buyer advice or demand. And after that, they will input that garment item into a poly-bag. And then, according to MCQ (Master carton quantity i.e. how many pieces would be packed in a carton box) for exportation.

And should check carefully every step that will help them to avoid claim after shipment.

**Moreover, check loading as well count carton onto vessel/container and accordingly should report to Management or Buyer. Generally, finishing section has to make a packing list as well. A packing list is much essential to make a commercial invoice and export documentation.

There are two packing way, mainly exist in the apparel industry. Please find the details below:

1. Solid packing

2. Assort packing.

Details of those above are as follows –

1. Solid packing

a) Solid color solid size: One particular color & particular size in a carton box.

b) Solid color assorts size: One specific color & different sizes in a carton box.

2. Assort or mixed packing

a) Assort color solid size: Different color & same size in a carton box.

b) Assort color assort size: Different color & different size in a carton box.

I have tried to present some packing list for your reference, but I’m unable to upload these packing lists in excel format due to some unavoidable circumstance. Thus, I am requesting you to download those packing list formats from my google drive link.

Please find a commercial invoice format for your reference from my google drive link. Please hit the link to download your desired file.

If anyone failed to get the “packing list format” from my google drive link, then please inform me for your required file. I will show my level best effort to provide your desired file as soon as possible through the mail.

Anyway, the format is not always kept fixed. It could be flexible or variable depends on practical situations. Nowadays, some company has integrated soft line packaging set up, including woven and printed fabric labels, all kinds of elastics, offset printed items, and heat transfer labels. Moreover, they can produce all types of poly including zip lock, blister bag etc and also can produce more than half a million-floor ready hangers a day.

Your valuable comments and necessary advice will encourage me to write more meaningful posts regarding garment sector.

You may like: How to Calculate Poly Bag Costing?

Leave a Reply

You must be logged in to post a comment.