What Are the Benefits of Using QR Codes?

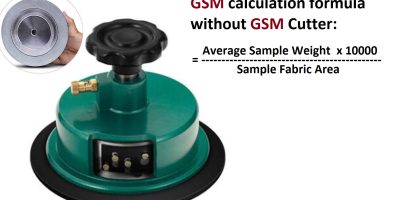

How to calculate GSM without GSM cutter?

How to Calculate Carton box Consumption?

How to Calculate Carton box costing?

12 Common factors that can improve embroidery quality

Key Factors of Embroidery Costing

How to Calculate Sewing Line Capacity of an Apparel Industry?

Bill of Material (BOM) in Apparel Industry