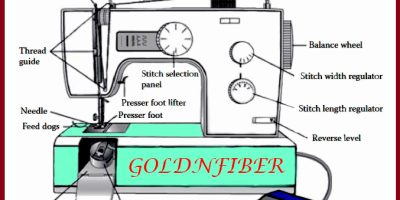

Domestic Sewing Machine is usually used in homes or tailoring shop. It is run by foot and may also be converted to the electrical power machine. There are numerous types of sewing machines engaged to make our wearers. When garment making process pulled from tailoring shop to industry, scientists invented industrial power generated sewing machines to meet the demands of fashion conscious people. Sewing machines are categorized depending on stitch classes,

Domestic Sewing Machine is usually used in homes or tailoring shop. It is run by foot and may also be converted to the electrical power machine. There are numerous types of sewing machines engaged to make our wearers. When garment making process pulled from tailoring shop to industry, scientists invented industrial power generated sewing machines to meet the demands of fashion conscious people. Sewing machines are categorized depending on stitch classes,seam types, number of needles used, table bed, utility etc. In the following list, we have tried to enclose most of the sewing machines those are employed in garment manufacturing process. You can read another article that was written by me to get more idea regarding garment business: Factors have to consider before setting up garment business in small scale.

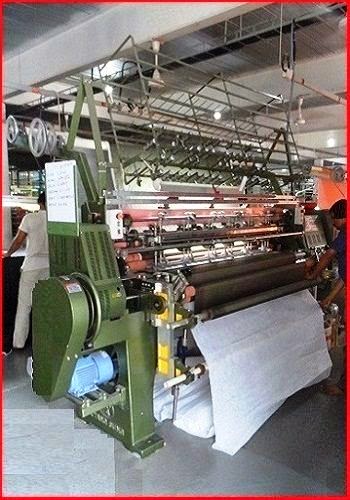

sewing machine with the help of operators. So, sewing section is the biggest part of any apparel industry. Production output and product quality mainly depend on the performance of sewing machinery.

B. Electrically operated sewing machine.

Usually, a sewing machine category can be defined according to its performance and stitch type. But we can classify it into two segments for your easy understanding.

Please find a narrative description regarding these two types of machines:

1) Manual sewing machine: The sewing machine which usually operated manually by the operator is treated as manual sewing machine. These types of machine are cheap and easy to use but not perfect for bulk production in the apparel industry. Because their output is slow considering others automated sewing machinery. Thus, it is always preferable in tailoring shop or home ground.

2) Electrical sewing machine:

The sewing machine which usually operated by using electrical power is treated as an electrical sewing machine. These types of sewing machine are little bit costly but perfect for bulk production in the apparel industry. Some of them are equipped with computer device. That auto generated pre-formatted sewing machine can perform continuously according to your command. Thus, garment manufacturers prefer it considering their high productivity.

Various types of Industrial sewing machines used in garments industry which are known as:

- Top & bottom cover stitch flat lock machine (cylinder bed and flat bed): It is a most common machine to produce knit or woven garments.

- Blind stitch machine: It is mainly used to sew bottom edge of pant.

- Single needle Lock stitch machine with or without trimmer is a perfect tool for tailoring shop or garment industry.

- Multi- needle industrial lock-stitch sewing machine with or without trimmer is perfect to split needle bar sewing or wiper and reverse feed. This type of machine mainly used to make decoration in woven garments.

- Over lock machine (1 needle 3 thread or 2 needles 4 thread machine): it is used to remove the raw edges from the pattern during garment assembling. Knit or woven both manufacturer like to use these machine. Knit garment requires light m/c, but woven garment needs heavy m/c.

- Interlock m/c (twin needle, 5-thread over-lock m/c): it is mainly used to trim the outline and stitch simultaneously. Woven or knit both garments like to use this machine to get outstanding performance.

- Single/double needle chain stitch m/c (Model# 380): This type of machine is preferable in woven or knit garments.

- Linking m/c: it is a common machine in sweater factory.

- Basting machine: It is used to do false sewing if require. Later it could be removed easily.

- Zigzag flatbed sewing m/c (1-needle): it is used to make twisted stitch for decorating garments.

- Feed of the Arm (double chain stitch m/c, 3-needle): for woven garment.

- Pin tucking machine: for labeling.

- Smoking machine/Automatic multi-needle shirring machine

- Button Hole m/c: it is used to attach button in the garments.

- Kansai m/c is useful for Button covering stitch belt loop

- Label/elastic inserting machine

- Bar tack m/c (with automatic thread trimmer): it is used to prevent reinforcement at the opening or closing position of any apparel.

- Shoulder pad-attaching machine

- Hemstitch machine for pant

- Collar and cuff turning and blocking machine and pressing device for shirt making

- QQ loop making m/c: it is used to make QQ loop

- Cycle machine for attaching Velcro, care label or patch label

- Skiving machine to reduce foam edge

- Embroidery machine

- Label/elastic inserting machine

- Lap seaming m/c (for back tape attaching)

- Chain stitch sewing machine

- Collar and cuff turning and blocking machine

- Over edging machine

- Bias tape cutting m/c

- Button attaching machine

- Double chain stitch m/c (double needle with reserve feed)

- Double chain stitch sewing m/c (4- needle elastic inserting m/c)

- Double chain stitch sewing machine (4- needle short)

Most of the models of industrial sewing machines have designed to accomplish a particular task. A single model has a single function, and it could not provide all that you desire. For example, there is a model particularly designed for sewing straight seams, a model for attaching buttons on garments, a model for creating zigzag stitches, a model for sewing cuffs, a model for doing interlock or over-lock etc. A well-selected sewing machine is necessary to achieve sound results. It should be used correctly in harmony with the job requirements. Thus, a production line or production floor has to be decorated with different types of industrial sewing machinery to gain its optimum level.

N.B: Though currently modern sewing machine manufacturer are producing multi- functional compatible digital sewing device but my suggestion is to decorate a sewing line by different types of high-performance user-friendly sewing machines which can do couple of tasks smoothly. However, I have tried to amalgamate various types of industrial sewing machines that are used in the garment industry. If I miss to enlist any useful sewing machine name in this article, please provide the sewing machine name below through your remarkable comments. I personally suggest you to procure branded dynamic sewing machinery for hassle free long term production. Never purchase so-called cheap and conventional machinery. It may bring a lot of trouble that will interrupt your productivity.

You may like: SOP of laser cut machine using in garments industry

Leave a Reply

You must be logged in to post a comment.